Grand River Rubber & Plastics is excited to announce Keith Wyatt as our new Chief Operating Officer. In his new role, Wyatt is responsible for Grand River Rubber & Plastics operations throughout its three product lines: lathe cut gaskets, vacuum sweeper belts, and drum and pail. Wyatt will drive alignment across these product lines to ensure operational excellence as the company expands its manufacturing footprint both domestically and internationally. Below, learn more about Wyatt’s manufacturing background and his perspective on the future of Grand River Rubber & Plastics.

Grand River Rubber & Plastics Blog

Keith Wyatt Brings 35 Years of Manufacturing Operations and Product Development Experience to Grand River Rubber & Plastics

Topics: employee ownership

Athletes Are No Longer 'Fit to be Tied' Thanks To Pretty Knotty's Innovative Product [Case Study]

Grand River Rubber & Plastics is proud to serve customers in a variety of industries and provide them with solutions to their biggest challenges. Below, learn how we helped Pretty Knotty develop an innovative hair tie designed for high-performance athletes.

Topics: Lathe Cut Gaskets

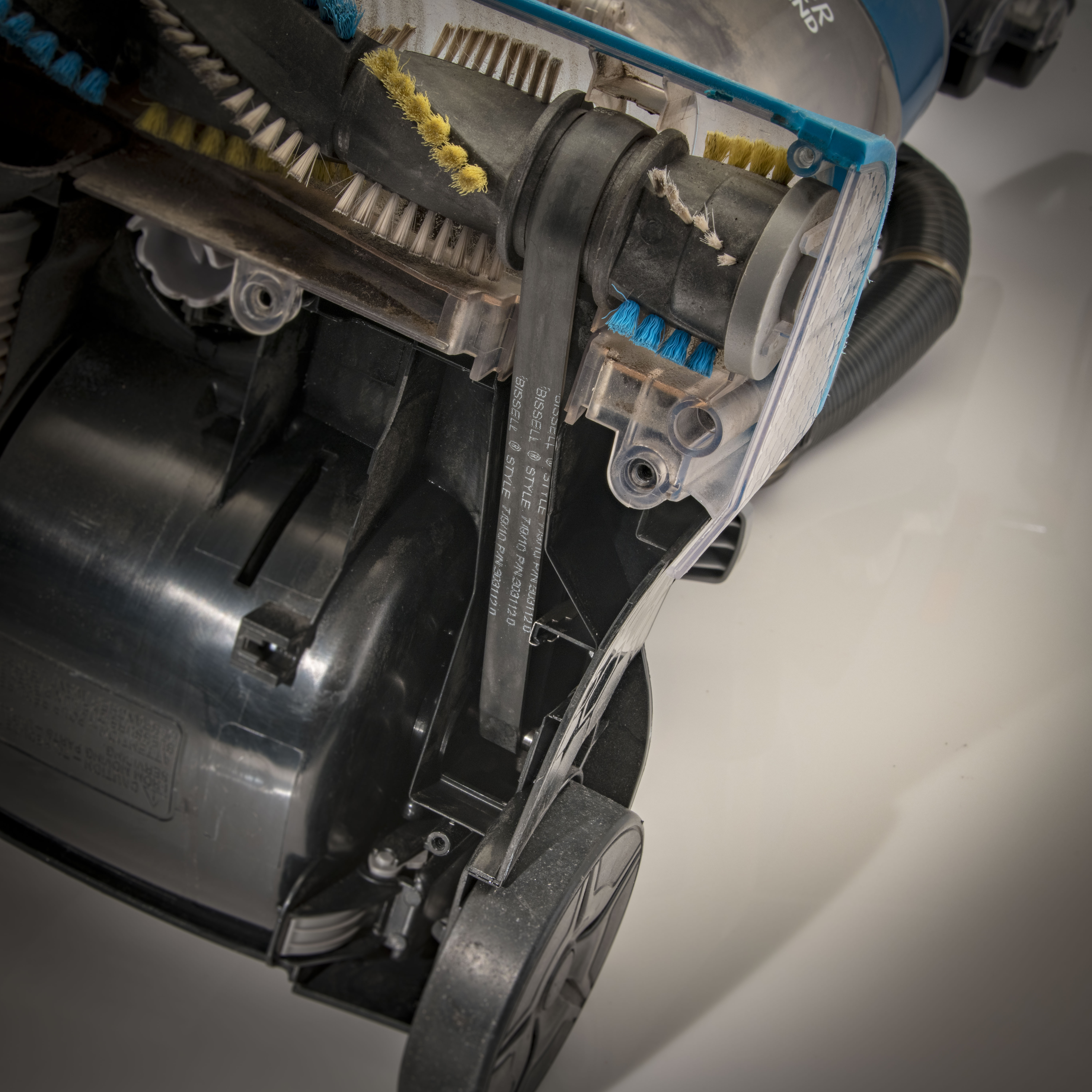

A Look Inside Grand River Rubber & Plastics Vacuum Belt Testing Lab

Topics: Vacuum Flat Belt

Bobby Nelson's career highlights the vast opportunities available in manufacturing careers

Bobby Nelson is a testament to the multitude of possibilities available in manufacturing careers. In his 20 years at Grand River, he has touched nearly every department at the company. Just over five years ago, Nelson joined the sales team at Grand River. He is evidence that with hard work and tenacity, you can accomplish anything. Hear Nelson’s take on his 2 decades in manufacturing and what he’s learned in his transition from the factory floor to sales below.

Topics: Lathe Cut Gaskets, drum & pail, employee ownership

Why Re-sellers Choose Grand River as Their Lathe Cut Gasket Provider

Topics: Lathe Cut Gaskets

Elite broadens scope with Wayne County Rubber purchase

Published by Rubber & Plastics News By BRUCE MEYER 10/9/18

Lathe cut gaskets offer unique advantages in comparison to O-rings, gaskets, and washers manufactured using other methods, such as die cutting or injection molding. The lathe cut process enables little or no tooling costs, smaller orders, the ability to make design changes easily, and rapid prototyping is as little as one week. At Grand River, we value our relationships with the re-sellers that carry our products. Below, learn some strategies re-sellers can use to sell more lathe cut gaskets.

How China Tariffs Are Impacting Your Gasket Prices

Topics: Lathe Cut Gaskets

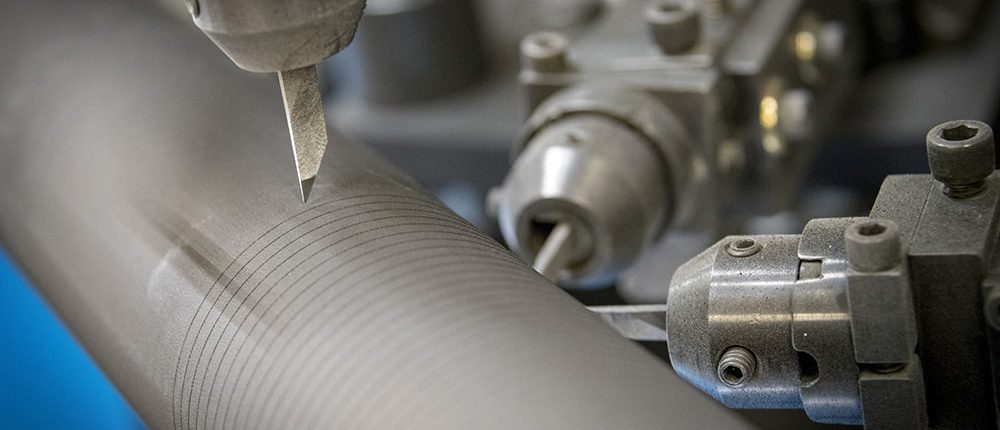

The Top 5 Reasons to Choose Lathe Cut Gaskets for Your Next Application

Lathe cut gaskets offers distinct advantages over O-rings, gaskets, and washers manufactured using other methods such as injection molding or die cutting. Learn the top 5 reasons to choose lathe cut gaskets for your next application over other methods.

Topics: Lathe Cut Gaskets

Grand River Rubber & Plastics Helps Restore 1913 Elevator at Historic San Diego Hotel [Case Study]

Grand River Rubber & Plastics strives to provide unmatched quality and top-of-the-line service. From management to each and every employee, our goal is to exceed customers’ expectations and provide high quality products. Below, learn how we helped repair an original 1913 elevator at a historic San Diego hotel in record time.

Topics: Lathe Cut Gaskets