Grand River Rubber & Plastics Blog

Bobby Nelson

Recent Posts

The Most Popular Cutting Styles of Gaskets & Their Advantages

Topics: Lathe Cut Gaskets

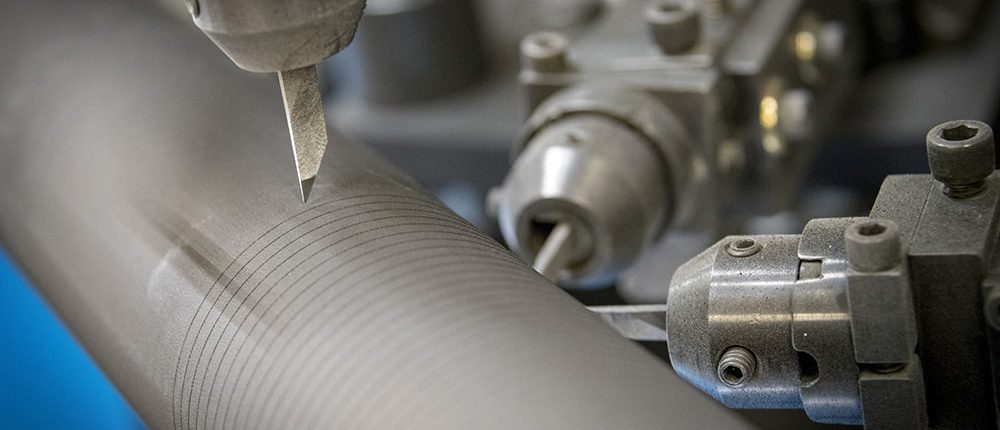

Choosing a sealant is one of the most important aspects of creating functionality and sustainability in your industrial and commercial products. Choosing the correct sealing solution is essential to keep debris out of your machinery and provide resistance to wear and tear. There are many sealing options available on the market including lathe cut gaskets, O-rings, quad seals, and die cut gaskets. In today’s blog, learn what lathe cut gaskets are, how they differ from O-Rings and quad seals, and how they benefit your products and machinery.

Topics: Lathe Cut Gaskets, orings, molded gaskets, die cut gaskets

Why Re-sellers Choose Grand River as Their Lathe Cut Gasket Provider

Topics: Lathe Cut Gaskets

Lathe cut gaskets offer unique advantages in comparison to O-rings, gaskets, and washers manufactured using other methods, such as die cutting or injection molding. The lathe cut process enables little or no tooling costs, smaller orders, the ability to make design changes easily, and rapid prototyping is as little as one week. At Grand River, we value our relationships with the re-sellers that carry our products. Below, learn some strategies re-sellers can use to sell more lathe cut gaskets.

The Top 5 Reasons to Choose Lathe Cut Gaskets for Your Next Application

Lathe cut gaskets offers distinct advantages over O-rings, gaskets, and washers manufactured using other methods such as injection molding or die cutting. Learn the top 5 reasons to choose lathe cut gaskets for your next application over other methods.

Topics: Lathe Cut Gaskets

Grand River Rubber & Plastics Helps Restore 1913 Elevator at Historic San Diego Hotel [Case Study]

Grand River Rubber & Plastics strives to provide unmatched quality and top-of-the-line service. From management to each and every employee, our goal is to exceed customers’ expectations and provide high quality products. Below, learn how we helped repair an original 1913 elevator at a historic San Diego hotel in record time.

Topics: Lathe Cut Gaskets

Grand River Rubber & Plastics Expansion Progresses

Grand River Rubber & Plastics is making progress on its 11,500 square foot manufacturing space expansion. The addition will be primarily used for Grand River's Drum & Pail production line and will be combination of manufacturing space and raw and finished goods storage. The addition will also create a second story office space that will provide future expansion.

Topics: drum & pail, Grand River Rubber & Plastics Expansion

Grand River Rubber & Plastics Commitment to Quality

Grand River Rubber & Plastics prides itself on providing unmatched quality and top-of-the-line service. From management to each and every employee, quality is part of our everyday business practice. Our goal is to consistently exceed our customers’ expectations. Below, learn about our strict quality policy and the steps we’ve taken to make the highest quality products possible.

Topics: Lathe Cut Gaskets, Quailty Policy

How to Choose NSF/ANSI Standard 61 Lathe Cut Gasket Materials for Drinking Water Systems

NSF/ANSI Standard 61 establishes health-related requirements that regulate drinking water supplies. NSF/ANSI 61 sets health effects criteria for many water system components including plumbing, process media, protective barrier materials, rubber seals and gaskets and more used in potable water systems.

Topics: Lathe Cut Gaskets, EDPM gaskets, NSF/ANSI Standard 61

Grand River Rubber & Plastics strives to manufacture products that meet our customers' requirements and exceeds their expectations. Responsiveness, quality products, competitive pricing and on time delivery are just part of our commitment. We also offer a variety of value add services which are outlined below.

Topics: Lathe Cut Gaskets