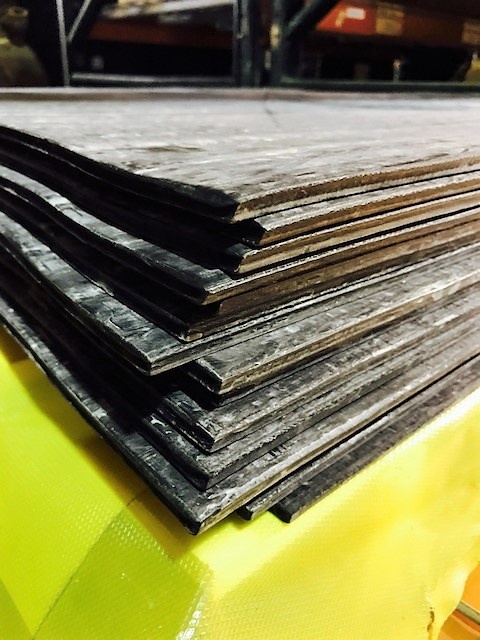

Choosing the correct lathe cut gasket materials for an application is a daunting task for many manufacturers. At Grand River, our extensive experience allows us to provide our customers with custom compounds that meet their specific needs while utilizing the most cost-effective materials. Below, we’ve listed some simple guidelines to assist you in choosing the correct material for your application.

Choosing a Gasket for Oil and Gas Applications

In applications where your gasket is in contact with oil or gas, it is usually favorable to use a nitrile rubber or NBR. Nitrile rubber is more resistant than natural rubber to oils and fuel. Nitrile contains various amounts of acrylonitrile, an ingredient which makes the material more or less oil/fuel resistant.

However, something important to keep in mind when using nitrile in an application, is that the level of acrylonitrile affects the gasket’s low temperature resistance. A nitrile high in acrylonitrile has poor low temperature resistance. While nitrile rubber has superior resistance to oil and gas, it is not the most weather resistance material and is best for enclosed applications.

Choosing a Gasket Material for Outdoor Applications

EPDM is a great material for outdoor applications. What makes EPDM unique is the elastomer’s ability to resist degradation from weathering agents like UV rays, ozone and heat. Additionally, EDPM is also very resistant to polar substances and steam.

Choosing a Gasket Material for Dynamic Applications

Natural rubbers & neoprene are good in dynamic applications, assuming the environment does not contain oil and gas. If the dynamic application has contact with oil and gas, HNBR is more favorable. Staff at Grand River can go into further detail about which material will work best for your dynamic application.

Choosing a Gasket Material for Food Grade Applications

Choosing materials for food grade applications can be a daunting task. The Food & Drug Administration provide details regarding the applications in which a material can be used and the percentage of that material that can be used in those applications in the Code of Federal Regulations Title 21.

If you have any questions about your food grade applications, give us a call. Our team has extensive knowledge and practical experience on the topic, as we are the only Lathe Cut Gasket Manufacturer recognized on the FDA’s Interstate Milk Shippers (IMS) List. We also have many customers that ship food grade products abroad and would be happy to assist you in choosing compliant materials.

In conclusion, we hope the information provided insight on how to choose the correct lathe cut gasket materials for your application. For a full list of our materials, check out our materials page. Have additional questions? Please contact our team below.